Consultancy

Manufacturing Process Consultancy

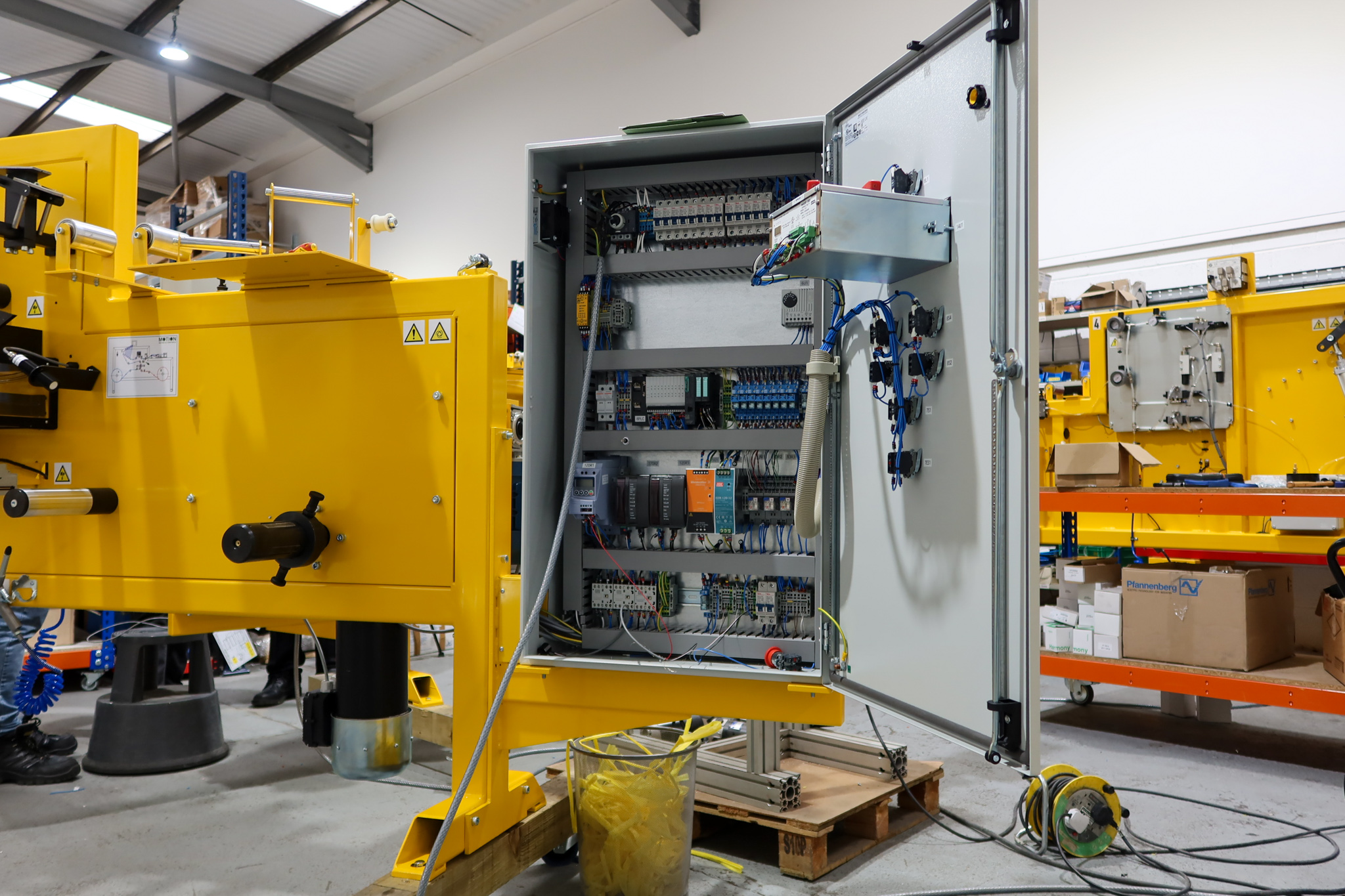

In the fast-paced world of manufacturing, optimising your production line is crucial for maintaining competitiveness and ensuring operational excellence. At Motion Drives & Controls, we offer expert onsite engineering production line consultancy services designed to streamline your processes, enhance productivity, and minimise costs. Our team of experienced consultants brings industry-leading expertise and a tailored approach to address your unique challenges. Discover how our consultancy services can transform your production line and drive your business forward.

-

Expertise Across Industries

-

Customised

Solutions -

Comprehensive

Support

Challenges You Face

-

Cost Overruns

Operational inefficiencies and wasted materials can drain your resources and impact your bottom line.

-

Downtime

Frequent breakdowns and maintenance issues disrupt production and cause delays.

-

Quality Control

Inconsistent product quality can lead to customer dissatisfaction and non-compliance with industry standards.

-

Inflexibility

A rigid production line makes it difficult to adapt to market changes and new product introductions.

Key Benefits of Our Consultancy Services

-

Increased

ProductivityOur consultancy services focus on optimising every aspect of your production line, from equipment layout and process flow to workforce management and automation. By eliminating bottlenecks, reducing waste, and streamlining processes, we help you achieve higher throughput and greater efficiency.

-

Cost

ReductionOperational inefficiencies can lead to significant costs in terms of wasted materials, energy consumption, and labour. Our experts identify and address these inefficiencies, helping you reduce operational costs and improve your bottom line. Additionally, we assist in implementing cost-effective technologies and practices that provide long-term savings.

-

Improved Flexibility and Scalability

In today’s dynamic market, the ability to adapt and scale your operations is crucial. We help you design flexible production lines that can quickly respond to changes in demand, new product introductions, and market trends. Our solutions ensure that your production line is not only efficient but also adaptable and scalable.

-

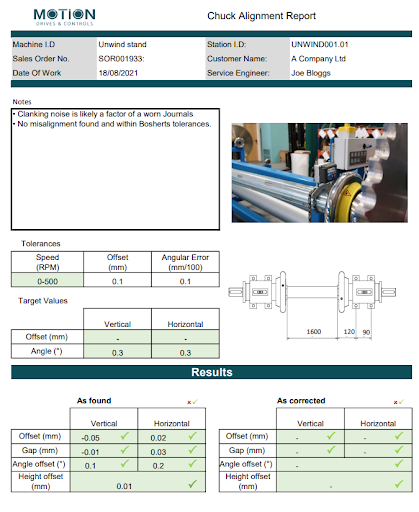

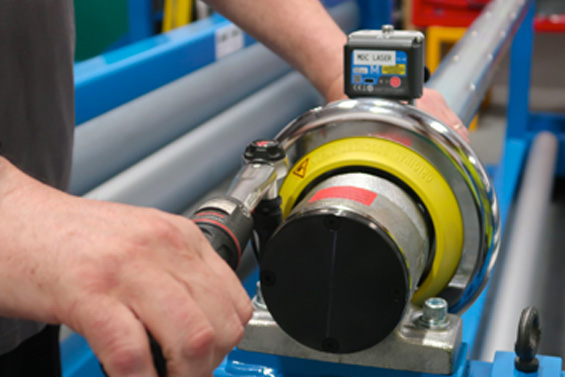

Enhanced Quality Control

Consistent product quality is essential for customer satisfaction and compliance with industry standards. Our consultancy services include the implementation of robust quality control systems and best practices, ensuring that your products meet the highest standards of quality and reliability.

Meet Your Guide: Motion Drives & Controls

We understand the complexities of engineering design, component supply, and machinery maintenance. Our professional team of engineers, based in Warwick, England, brings industry-leading expertise and a hands-on approach to help you achieve operational excellence.

How it Works

-

1. Initial Consultation and Assessment

Our consultancy process begins with an initial consultation to understand your specific needs and objectives. We conduct a detailed assessment of your production line, gathering data on key performance indicators, workflow processes, equipment efficiency, and overall operational performance.

-

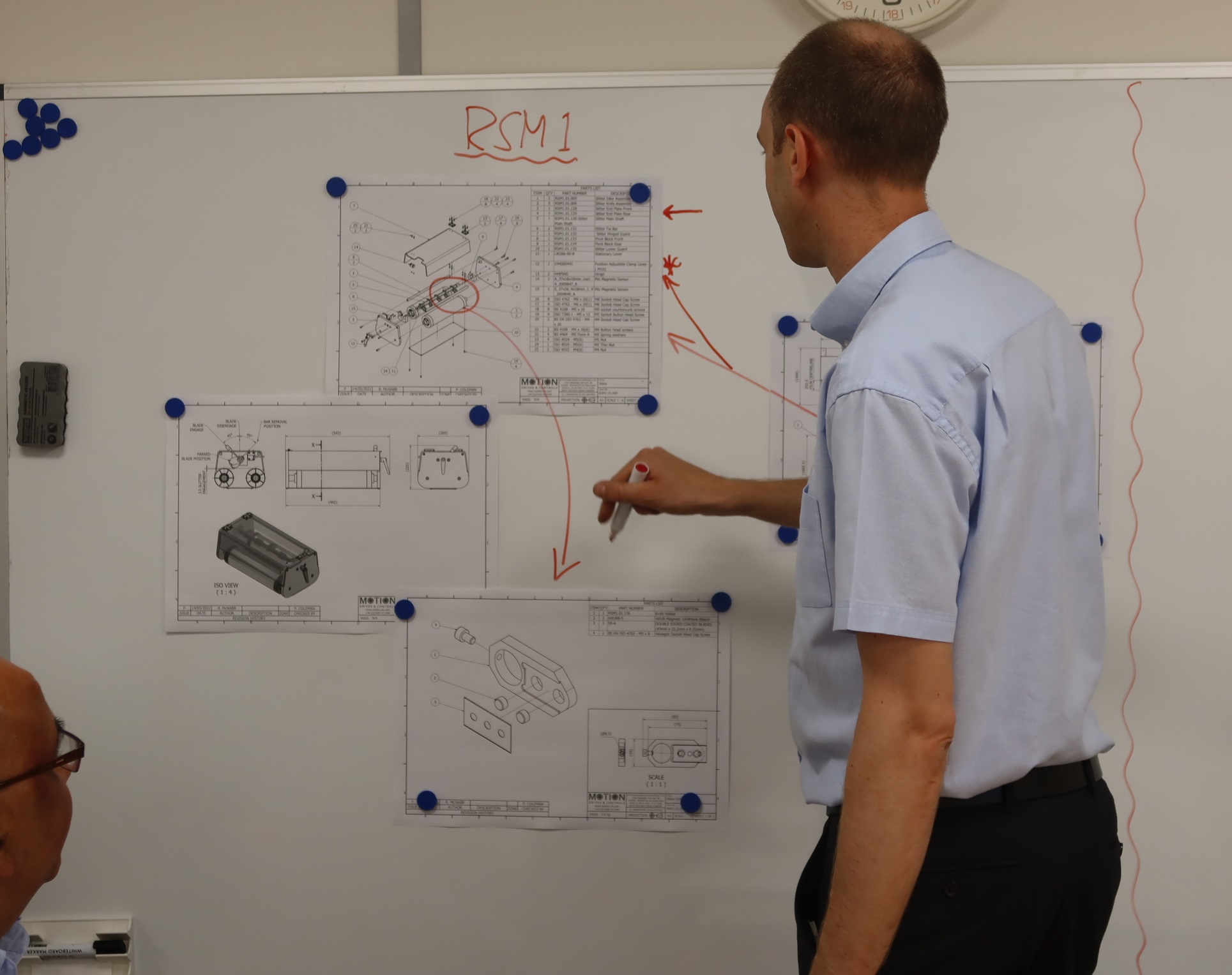

2. Data Analysis and Diagnosis

Using the data collected during the assessment, we perform a comprehensive analysis to identify bottlenecks, inefficiencies, and areas for improvement. Our experts use advanced analytical tools to diagnose the root causes of issues and develop actionable insights.

-

3. Strategy Development

Based on our analysis, we develop a customized strategy to optimize your production line. This strategy includes specific recommendations for process improvements, equipment upgrades, workforce training, and quality control measures. We provide a detailed implementation plan with clear timelines and milestones.

-

4. Implementation and Monitoring

Our consultants work closely with your team to implement the recommended changes. We provide hands-on support during the implementation phase, including training and troubleshooting. We also establish monitoring systems to track the performance of the production line and ensure that improvements are sustainable.

-

5. Continuous Improvement

Our commitment to your success doesn’t end with implementation. We offer ongoing support to help you continuously improve your production line. This includes regular reviews, performance audits, and the introduction of new technologies and practices as needed.

Let’s Optimise Your Production Line Together

At Motion Drives & Controls, we are committed to helping you achieve operational excellence through our tailored onsite engineering production line consultancy services. Whether you’re aiming to boost productivity, reduce costs, or enhance quality, our team is here to guide you every step of the way.

Contact us today to learn more about how our consultancy services can transform your production line and support your business growth. Together, let’s build a more efficient, productive, and profitable future.

- Hits: 3663