In this Article

Servo motors are ubiquitous in the realm of automation and robotics, powering everything from industrial machines to medical devices. These motors provide precise control over motion, enabling robots to pick and place objects with incredible accuracy and manufacturing processes to run smoothly. However, there are times when you need to stop or hold the motor's movement securely. This is where servo motor brakes come into play.

Servo motor brakes are specialised devices designed to provide controlled braking or holding torque to servo motors when needed. They ensure that the motor stops or maintains its position with precision, adding an extra layer of safety and control to various applications. In the following sections, we will explore the world of servo motor brakes, from their types to their applications and the market leaders who manufacture them.

- Servo Motor Brakes: Specialised devices providing precise control and stopping power for servo motors in automation and robotics.

- Two Types: Electromagnetic brakes for quick response and spring-applied brakes for fail-safe operation.

- Key Features: High torque, zero backlash, quick response time, and low inertia enhance performance and precision.

- Applications: Widely used in industrial automation, robotics, and medical devices for safety and precision.

- Benefits: Longevity, customisation options, and safety measures, with fail-safe operations as a standard feature.

What Are Servo Motor Brakes?

Servo motor brakes are electromechanical devices that work in conjunction with servo motors. They are used to stop, hold, or control the motion of a servo motor shaft. These brakes are essential in applications where precise positioning and control are required, such as robotics, CNC machines, and conveyor systems.

Servo motor brakes can be categorised into two main types:

Types of Servo Motor Brakes

Electromagnetic Brakes

Electromagnetic servo motor brakes use the principle of electromagnetism to generate braking force. When an electrical current is applied to the brake coil, it creates a magnetic field that attracts an armature plate, thus engaging the brake. This action prevents the motor shaft from rotating, providing the necessary holding torque.

One of the key advantages of electromagnetic brakes is their quick response time. They can engage and disengage almost instantly, making them suitable for applications that require rapid stopping and starting.

Spring-Applied Brakes

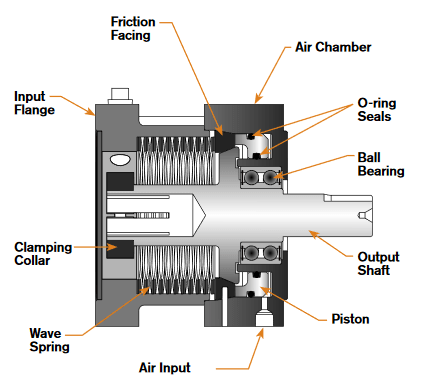

Spring-applied servo motor brakes, as the name suggests, rely on the force of a spring to engage the brake. When an electrical current is removed or a failure occurs, the spring force pushes a frictional element against the rotor, halting the motor's motion.

Spring-applied brakes are known for their fail-safe operation. In the event of a power outage or system failure, the brake automatically engages, preventing any unintended motion.

Key Features

(Source: Rexel)

Servo motor brakes offer several key features that make them indispensable in various applications. Here are some of the most notable features:

High Torque

Servo motor brakes are designed to provide high torque in a compact form factor. This ensures that they can effectively stop and hold the motor shaft, even in high-speed applications.

Zero Backlash

Backlash refers to the clearance or play between moving parts in a mechanical system. Servo motor brakes are engineered to minimise or eliminate backlash, ensuring precise and repeatable positioning.

Quick Response Time

One of the standout features of servo motor brakes, especially electromagnetic ones, is their rapid response time. They can engage and disengage almost instantaneously, allowing for precise control over motion.

Low Inertia

Servo motor brakes are designed to have low inertia, meaning they don't add significant mass or resistance to the motor shaft. This ensures that the overall performance of the servo system remains optimal.

Applications

Servo motor brakes find applications in a wide range of industries and scenarios where precise motion control and safety are paramount. Here are some of the key sectors where these brakes are commonly used:

Industrial Automation

In industrial automation, servo motor brakes play a crucial role in conveyor systems, robotic arms, and CNC machines. They help ensure that machinery stops precisely when required, contributing to efficient and safe manufacturing processes.

Robotics

Robots are becoming increasingly prevalent in various industries, from manufacturing to healthcare. Servo motor brakes are essential for robotic arms and joints, enabling them to move with precision and stop accurately.

Medical Devices

In the medical field, precision is of utmost importance. Servo motor brakes are used in medical devices such as surgical robots and diagnostic equipment, ensuring that these devices operate with precision and safety.

Benefits and Advantages

Now that we've explored the key features and applications of servo motor brakes, let's take a closer look at the benefits and advantages they offer:

Long Life

Servo motor brakes are built to withstand continuous use and provide long-lasting performance. This longevity is crucial in industries where downtime can be costly and disruptive.

Safety Measures

In many applications, especially those involving heavy machinery or robotics, safety is a top priority. Servo motor brakes enhance safety by ensuring that motion is controlled and can be halted when necessary.

Customisation Options

Manufacturers of servo motor brakes often offer customisation options to meet the specific needs of different applications. This adaptability ensures that the brakes can be tailored to suit various industries and requirements.

How They Work

To better understand how servo motor brakes operate, let's delve into their basic mechanism and fail-safe operations.

Basic Mechanism

In both electromagnetic and spring-applied brakes, the basic principle involves the engagement of a frictional element when the brake is activated. This frictional element creates resistance against the motor's rotation, bringing it to a stop or holding it in place.

Electromagnetic brakes rely on the magnetic force generated by an energised coil to attract an armature plate, compressing a set of friction disks and causing the brake to engage. When the coil is de-energised, the magnetic force diminishes, allowing the spring to disengage the brake.

Spring-applied brakes, on the other hand, employ a spring to apply pressure to the friction element. When the brake is activated, the spring tension is released, pushing the friction element against the rotor and engaging the brake. To release the brake, an electrical current is applied, counteracting the spring force.

Fail-Safe Operations

The fail-safe nature of servo motor brakes is a crucial aspect of their design. In the event of a power loss or system failure, these brakes are engineered to engage automatically, preventing unintended motion. This fail-safe feature enhances safety in applications where sudden stops are critical.

Market Leaders and Their Offerings

Several companies specialise in manufacturing high-quality servo motor brakes. Here are some of the market leaders and a brief overview of their offerings:

1) KEB America

KEB America is a well-known manufacturer of industrial automation components, including servo motor brakes. They offer a range of electromagnetic brakes known for their reliability and precision. KEB's brakes are used in a variety of applications, from packaging machinery to automotive assembly lines.

2) Stearns Brakes

Stearns Brakes has a long history of producing top-notch industrial brakes, including those designed for servo motors. Their brakes are known for their durability and ability to withstand harsh industrial environments. Stearns Brakes cater to a wide range of industries, from mining to agriculture.

3) Nexen Group

Nexen Group specialises in motion control solutions, and their servo motor brakes are no exception. They offer a variety of spring-applied brakes designed for precision and safety. Nexen Group's brakes are commonly used in robotics and automation systems.

4) Mayr

Mayr is a global leader in the field of mechanical and electromagnetic clutches and brakes. They offer a comprehensive range of servo motor brakes that are known for their high torque, precision, and reliability. Mayr's brakes are widely used in machine tools, printing presses, and more.

5) Warner Electric

Warner Electric is a trusted name in the world of industrial clutches and brakes. Their servo motor brakes are designed for applications where precision and responsiveness are critical. These brakes find applications in packaging machinery, material handling, and more.

6) Quicksilver Controls

Quicksilver Controls specialises in motion control technology, and their servo motor brakes are designed to complement their innovative products. Quicksilver Controls' brakes are known for their compact design and quick response times, making them ideal for robotics and automation.

Conclusion

Servo motor brakes are an integral part of the automation and robotics landscape, providing the necessary control and safety measures for precise motion. From their high torque and quick response time to their fail-safe operations, these brakes offer a wide range of benefits. Whether you're working on an industrial assembly line or exploring the world of robotics, servo motor brakes are essential for achieving precise and controlled motion.

As technology continues to advance, we can expect servo motor brakes to evolve further, offering even more capabilities and customisation options to meet the ever-changing demands of modern industries. So, the next time you see a robot performing intricate tasks or a conveyor system moving products with precision, remember that servo motor brakes are working behind the scenes to make it all possible.

FAQs

Servo motor brakes are used to stop, hold, or control the motion of a servo motor shaft in applications where precise positioning and safety are crucial. They provide controlled braking or holding torque to ensure that the motor stops or maintains its position accurately.

There are two main types of servo motor brakes: electromagnetic brakes and spring-applied brakes. Electromagnetic brakes use electromagnetism to generate braking force, while spring-applied brakes rely on a spring to engage the brake when an electrical current is removed or a failure occurs.

Servo motor brakes are considered fail-safe because they are designed to engage automatically in the event of a power loss or system failure. This ensures that unintended motion is prevented, enhancing safety in critical applications.

Servo motor brakes find applications in various industries, including industrial automation (conveyor systems, CNC machines), robotics (robotic arms and joints), and medical devices (surgical robots and diagnostic equipment), among others. They are used wherever precise motion control and safety are essential.

Several leading manufacturers of servo motor brakes include KEB America, Stearns Brakes, Nexen Group, Mayr, Warner Electric, and Quicksilver Controls. These companies offer a wide range of servo motor brakes known for their reliability, precision, and durability.