In this Article

In various industries, precise measurement of weight and force is crucial for ensuring safety, quality control, and performance optimisation. Load cells play a fundamental role in achieving accurate measurements, making them an indispensable tool for engineers, researchers, and professionals working in diverse fields such as manufacturing, aerospace, automotive, healthcare, and more.

In this comprehensive guide, we will delve into the world of load cells, demystifying their workings, exploring the different types, uncovering their applications, and providing essential tips on selecting and maintaining the right load cell for your specific needs.

What is a Load Cell?

A load cell is a transducer, an electronic device capable of converting a mechanical force or load into an electrical signal. In simpler terms, it converts the weight or force applied to it into an electrical output, which can be easily measured and analysed.

Load cells are often used in conjunction with scales, balances, and other measuring instruments to accurately determine the weight of objects or forces acting on structures.

How Does a Load Cell Work?

Load cells operate on the principle of strain. When a load is applied to a load cell, it deforms slightly due to the stress exerted on it. This deformation leads to a change in its resistance or voltage output, which is directly proportional to the applied force.

The load cell's internal components, such as strain gauges or piezoelectric materials, detect these changes and convert them into an electrical signal.

Working Principle

Source: Wikipedia

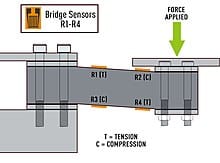

The working principle of a load cell varies depending on its type. In general, strain gauge load cells use strain gauges bonded to a metal element to measure the deformation caused by the applied force.

Hydraulic and pneumatic load cells rely on fluid pressure changes, while capacitive load cells utilise changes in capacitance, and piezoelectric load cells generate an electric charge in response to mechanical stress.

Types of Load Cells

Strain Gauge Load Cells

Strain gauge load cells are the most common type and come in various configurations, including bending beam, shear beam, and S-type. They use a set of strain gauges attached to a metal element, and as the metal element deforms under the applied load, the strain gauges experience changes in resistance, providing accurate measurements.

Hydraulic Load Cells

Hydraulic load cells operate by measuring the pressure of a hydraulic fluid, which changes with the applied force. These load cells are known for their ruggedness and high capacity, making them suitable for heavy-duty applications.

Pneumatic Load Cells

Pneumatic load cells measure the air pressure changes caused by the applied force. They are commonly used in industries where electrical signals might pose safety hazards, such as hazardous environments or explosive atmospheres.

Capacitive Load Cells

Capacitive load cells measure the change in capacitance resulting from the applied force. These load cells offer high accuracy and are less prone to electromagnetic interference, making them suitable for precise applications.

Piezoelectric Load Cells

Piezoelectric load cells use piezoelectric materials that generate an electric charge when subjected to mechanical stress. They are highly sensitive and widely used in dynamic force measurements, such as impact testing and vibration analysis.

Applications

Load cells find applications across numerous industries, some of which include:

- Manufacturing: Load cells are used in production lines to monitor material levels, ensuring precise filling, packaging, and quality control.

- Aerospace: Load cells play a vital role in aircraft weight and balance calculations, structural testing, and aerospace research.

- Automotive: Load cells are used in automotive testing to evaluate vehicle components and performance, including suspension systems, braking systems, and engine testing.

- Healthcare: In the medical field, load cells are employed in patient lifting equipment, prosthetic limb testing, and rehabilitation devices.

- Material Handling: Load cells are used in crane scales, forklifts, and conveyor systems to measure weight and prevent overloading.

- Research and Development: Load cells are essential in scientific research, enabling precise force measurements in experiments and testing.

Choosing the Right Load Cell

Specifications

When selecting a load cell for your specific application, several key specifications should be considered:

- Capacity: The maximum load the load cell can measure without damage or loss of accuracy.

- Accuracy: The degree of precision in the load cell's measurements.

- Environment: Consider the operating environment, including temperature, humidity, and potential exposure to chemicals or dust.

- Mounting: The load cell's mounting method must be compatible with the application and ensure proper load transmission.

- Output Signal: Determine the type of output signal required, such as analogue voltage, current, or digital.

Calibration

Load cell calibration is crucial to ensure accurate and reliable measurements. Regular calibration helps identify any drift or changes in performance, allowing for adjustments or replacements as necessary. It is advisable to have load cells calibrated by accredited calibration laboratories to ensure traceability and compliance with industry standards.

Load Cell Designs

Load cells come in various designs, each tailored to specific applications. Some common designs include:

- Single-Point Load Cells: Suitable for weighing small to medium-sized objects, they are often used in retail scales and bench scales.

- S-Type Load Cells: Resemble the letter 'S' and are commonly used in tension and compression applications.

- Shear Beam Load Cells: Designed for medium to high-capacity measurements and are commonly used in industrial weighing systems.

- Canister Load Cells: Ideal for high-capacity applications such as truck scales and tank weighing.

Caring for Your Load Cell

To ensure the longevity and accuracy of your load cell it’s important to care for it properly; consider the following care tips:

- Avoid Overloading: Always use the load cell within its specified capacity to prevent damage.

- Regular Inspection: Periodically inspect the load cell for any signs of wear, damage, or contamination.

- Correct Installation: Follow the manufacturer's guidelines for proper installation to ensure accurate readings.

- Environmental Protection: Shield the load cell from harsh environmental conditions, such as extreme temperatures and moisture.

Load cells are essential tools in the world of precise measurements, finding applications across various industries and research fields. Understanding the principles, types, and applications of load cells is vital for selecting the right one for your specific needs. By mastering load cells, you can ensure accurate measurements, optimise processes, and enhance safety in your industry.

Remember, when choosing a load cell, consider its capacity, accuracy, environment, and mounting requirements. Regular calibration and proper care will keep your load cell in top condition and provide reliable data for years to come.

By grasping the concepts presented in this guide, you are now better equipped to navigate the world of load cells and make informed decisions in your professional endeavours. Embrace the power of load cells and unlock their potential in enhancing efficiency and performance in your industry.

Conclusion

In the realm of engineering, from chemical engineering to environmental engineering, load cells have proven to be indispensable tools for precise measurement and control systems. Their applications are vast, extending across various sectors such as manufacturing, aerospace, and healthcare, solving real-world problems that require meticulous attention to weight and force measurements.

For civil engineers and those in structural engineering, load cells offer invaluable data that can be used in the design and testing of buildings, bridges, and other infrastructures. They are crucial in weighing applications, ensuring that materials are used efficiently and safely. In the industrial applications sector, they play a pivotal role in quality control and process optimisation.

The diverse types of load cells, including strain gauge, hydraulic, pneumatic, capacitive, and piezoelectric, each come with their unique advantages and are suited for specific environments. For instance, compression load cells are often used in heavy-duty applications where high capacity is required.

Understanding the physics and chemistry behind how load cells work can provide engineers with the knowledge needed to select the right type of load cell for their specific needs. Regular calibration, preferably conducted by accredited laboratories recognised by the Engineering Council, ensures that these devices maintain their accuracy and reliability over time.

In summary, load cells are more than just measuring devices; they are integral components in a wide array of engineering applications that demand precision, reliability, and durability. By making informed choices based on capacity, accuracy, and environmental conditions, professionals can harness the full potential of load cells to enhance efficiency and solve complex engineering challenges.

By embracing the power of load cells, you're not just making an investment in a piece of equipment; you're investing in the assurance of quality, safety, and efficiency across multiple engineering disciplines.

FAQs

Load cells are extensively used in manufacturing, aerospace, automotive, healthcare, material handling, and research and development. They play a crucial role in ensuring quality control, process monitoring, weight measurement, safety systems, patient monitoring, experimental setups, and scientific research across various industries.

The main types of load cells are strain gauge, hydraulic, pneumatic, capacitive, and piezoelectric load cells, each with distinct working principles and applications.

Strain gauge load cells gauge deformation through electrical resistance changes, while hydraulic ones use pressurised fluid and pneumatic cells utilise air pressure changes.

Capacitive load cells measure force through capacitance changes, and piezoelectric load cells generate an electric charge when subjected to force, making them suitable for dynamic force measurements.

Strain gauge load cells work based on the principle that when an external force is applied, the metal element to which the strain gauge is bonded undergoes deformation, leading to a change in electrical resistance within the strain gauge.

This change in resistance is proportional to the applied force, enabling the load cell to accurately convert mechanical force into an electrical signal that can be measured and quantified.

Piezoelectric load cells offer high sensitivity and are ideal for dynamic force measurements in impact testing and vibration analysis. Their exceptional responsiveness allows for precise measurements even for small forces.

Due to their wide frequency range, piezoelectric load cells are suitable for measuring rapid force changes. Moreover, they are compact, portable, and consume low power, making them versatile and easy to use in various applications.

Load cells should be calibrated regularly, preferably by accredited calibration laboratories, to ensure accuracy and compliance with standards. The calibration frequency depends on usage, environmental conditions, and industry requirements.

For critical applications, more frequent calibrations are recommended. Generally, an annual calibration suffices for most cases, but heavy usage or extreme conditions may necessitate more frequent checks to maintain reliable force measurements and traceability.