In this Article

Cable and hose carriers are essential components in industrial machinery and automation systems. They serve a vital purpose by protecting and guiding cables, hoses, and other vital connections within a machine or robotic system. These carriers ensure that these components remain organised, safe, and protected from damage during movement and operation. This article will explore the world of cable and hose carriers, covering various aspects such as types, design considerations, installation guidelines, and applications. Understanding these aspects is crucial for engineers, technicians, and anyone interested in the field of automation and machinery.

- Protection and Organisation: Cable and hose carriers safeguard cables and hoses from environmental factors and help organise them, enhancing safety and reducing wear.

- Types and Materials: Available in plastic and steel, carriers vary in weight, durability, and suitability for different industrial environments.

- Design Factors: Important design aspects include the maximum cable and hose diameters, bending radius, and separation and distribution within the carrier.

- Installation Best Practices: Strain relief for electrical cables, secure attachment for pneumatic hoses, and careful installation for hydraulic hoses are essential.

- Wide-Ranging Applications: They are used across various sectors, such as robotics, material handling, machine tools, textiles, and water treatment, to improve efficiency and safety.

What are Cable and Hose Carriers?

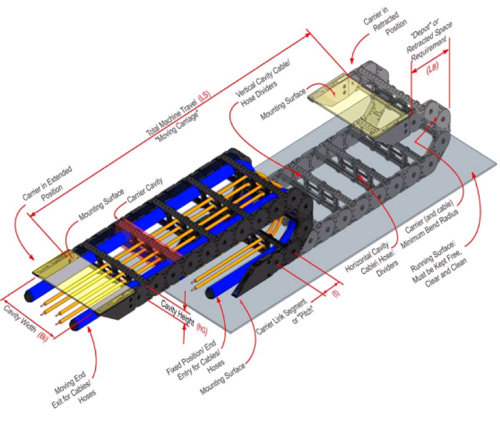

Cable and hose carriers, also known as cable chains, drag chains, or energy chains, are protective and guiding systems designed to manage and safeguard cables, hoses, and other lines used in machinery and automation. These carriers consist of interconnected links that form a flexible chain-like structure, allowing for the smooth movement of cables and hoses while preventing tangling or damage.

(Source: Wire & Cable Tips)

The primary functions of cable and hose carriers are as follows:

- Protection: They shield cables and hoses from environmental factors such as dust, debris, moisture, and chemicals, extending their lifespan.

- Guidance: By guiding cables and hoses along a defined path, carriers ensure smooth and precise movement within the machinery, reducing the risk of snagging or tangling.

- Organisation: They help organise and bundle multiple cables and hoses, ensuring a neat and compact arrangement.

- Safety: Cable and hose carriers enhance safety by preventing tripping hazards and reducing wear and tear on cables and hoses, which can lead to unexpected failures.

Types of Cable Carriers

Cable and hose carriers come in various types, each with its unique features and benefits. Let's explore two common types:

Plastic Cable Carriers

Plastic cable carriers, often made of materials like nylon or polypropylene, are lightweight and cost-effective. They are ideal for applications where weight is a critical factor. Plastic carriers are corrosion-resistant and offer good resistance to chemicals. They are commonly used in industries like packaging, printing, and light manufacturing.

Steel Cable Carriers

Steel cable carriers are robust and durable, making them suitable for heavy-duty applications. They provide excellent protection against mechanical stress, such as impacts and abrasion. Steel carriers are commonly used in industries like automotive manufacturing, steel mills, and heavy machinery. Choosing between plastic and steel carriers depends on the specific application's requirements, including load capacity, environment, and budget considerations.

Design Considerations

When selecting cable and hose carriers for an application, several design considerations must be taken into account to ensure optimal performance:

Maximum Cable and Hose Diameters

One crucial consideration is the maximum diameter of the cables and hoses that the carrier can accommodate. It's essential to choose a carrier size that allows all the required cables and hoses to fit comfortably.

Bending Radius

The bending radius represents the minimum allowable curvature of cables and hoses within the carrier. It's crucial to ensure that the carrier's bending radius is compatible with the cables' specifications to prevent kinking or damage.

Separation and Distribution Rules

Cables and hoses within the carrier should be adequately separated to prevent interference and abrasion. Distributing them evenly within the carrier ensures a balanced load distribution.

Installation Guidelines

Proper installation of cable and hose carriers is essential to ensure their effectiveness and longevity. Here are some installation guidelines for different types of lines:

Strain Relief of Electrical Cables

When installing electrical cables within a carrier, it's crucial to provide adequate strain relief at both ends. This prevents excessive tension on the cables and reduces the risk of damage or disconnection.

Pneumatic Hose Installation

When installing pneumatic hoses, ensure that they are securely attached to the carrier. Proper anchoring prevents hoses from shifting or tangling during operation.

Hydraulic Hose Installation

Hydraulic hoses should be installed with care to avoid sharp bends or kinks. Adequate support and routing are essential to maintain hose integrity and prevent leaks.

Applications

Cable and hose carriers find applications in various industries, contributing to the efficiency and safety of automated systems. Here are some notable applications:

Robotics

In robotics, cable and hose carriers play a critical role in guiding and protecting the numerous cables and hoses that power and control the robot's movements and functions. These carriers enable robots to move freely without the risk of cable damage or entanglement.

Handling

Conveyor systems and material handling equipment use cable and hose carriers to ensure the safe and reliable transport of goods. These carriers protect power and control cables, as well as hydraulic and pneumatic hoses, in applications ranging from warehouses to manufacturing facilities.

Machine Tools

Machine tools, such as CNC machining centres and lathes, rely on cable and hose carriers to manage the cables and hoses that power and control their operations. These carriers ensure that the machinery operates smoothly and accurately.

Textile Industries

Textile manufacturing machinery often involves complex movements and high-speed operations. Cable and hose carriers are used to manage the various lines needed for spinning, weaving, and dyeing processes, ensuring uninterrupted production.

Water Treatment Plants

Water treatment facilities utilise cable and hose carriers to protect and guide cables and hoses in pumps, valves, and control systems. These carriers help maintain the reliability and efficiency of the treatment process.

Benefits and Value

The use of cable and hose carriers offers several benefits and adds significant value to industrial applications:

Reducing Wear and Stress

By preventing cables and hoses from rubbing against sharp edges or moving parts, cable carriers reduce wear and stress on these vital components. This extends their service life and reduces the frequency of maintenance and replacements.

Improving Safety

Cable and hose carriers enhance workplace safety by minimising tripping hazards and preventing cable damage that could lead to electrical or fluid leaks. In environments where human workers interact with machinery, this is particularly important.

Conclusion

Cable and hose carriers are unsung heroes in the world of industrial automation and machinery. They provide essential protection, guidance, and organisation for cables and hoses, contributing to the smooth and safe operation of various systems across different industries. Whether in robotics, handling, machine tools, textiles, or water treatment plants, these carriers play a vital role in ensuring efficiency and safety.

As technology continues to advance, the demand for innovative cable and hose carrier solutions will grow. Engineers and designers will continue to develop new designs and materials to meet the evolving needs of the industry. With a better understanding of cable and hose carriers, we can appreciate their importance and the role they play in shaping our automated world.

FAQs

Cable and hose carriers are protective and guiding systems designed to manage and safeguard cables, hoses, and other lines used in machinery and automation. They consist of interconnected links that form a flexible chain-like structure, allowing for easy installation and maintenance.

The primary functions of cable and hose carriers include protection, guidance, organisation, and safety. They shield cables and hoses from environmental factors, guide them along a defined path, organise multiple lines, and enhance workplace safety by reducing the risk of accidents and equipment damage.

There are two common types of cable carriers: plastic cable carriers and steel cable carriers. Plastic carriers are lightweight and cost-effective, while steel carriers are robust and durable, suitable for heavy-duty applications where strength and longevity are paramount.

Design considerations include maximum cable and hose diameters, bending radius, and separation and distribution rules. These factors ensure that the carrier is compatible with the cables and hoses it will house, preventing stress on the lines and ensuring optimal performance.

Cable and hose carriers find applications in robotics, handling, machine tools, textile industries, and water treatment plants. They contribute to the efficiency and safety of automated systems in these industries, reducing downtime and maintenance costs.

Cable and hose carriers improve safety by minimising tripping hazards and preventing cable damage that could lead to electrical or fluid leaks. They are particularly important in environments where human workers interact with machinery, helping create a safer workplace environment.

Yes, cable and hose carriers can be customised to meet specific requirements, including length, configuration, and material selection, ensuring they are tailored to the unique demands of various industrial applications. Customisation helps optimise cable and hose management for improved efficiency and longevity. At Motion, we offer tailored solutions to a wide range of industries and customers.