Leading Providers of Industrial Automated Solutions.

As the leading distributor and system integrator of drives and transmission equipment into the Engineering industry in the UK, Ireland and Continental Europe, you get one source of dependability and convenience.

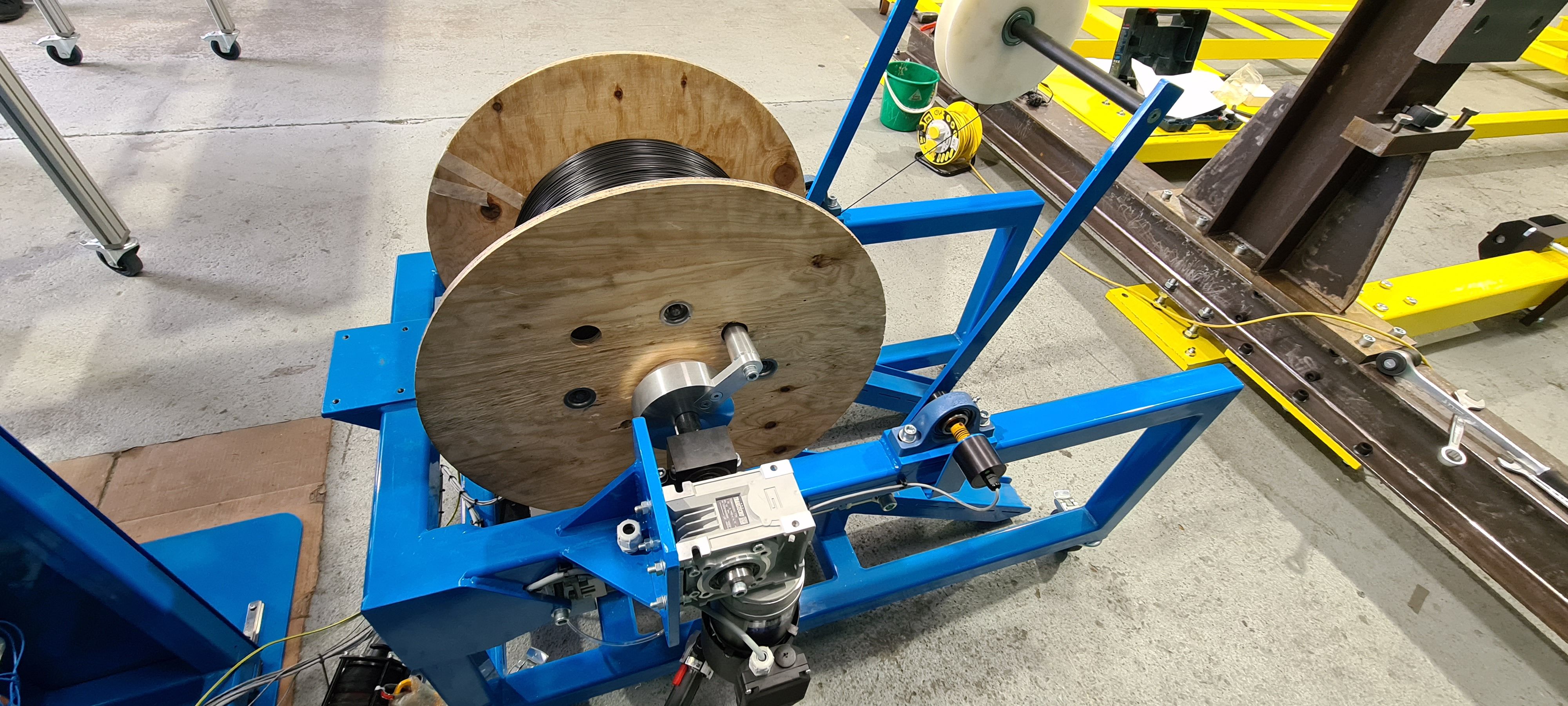

Unwind stand

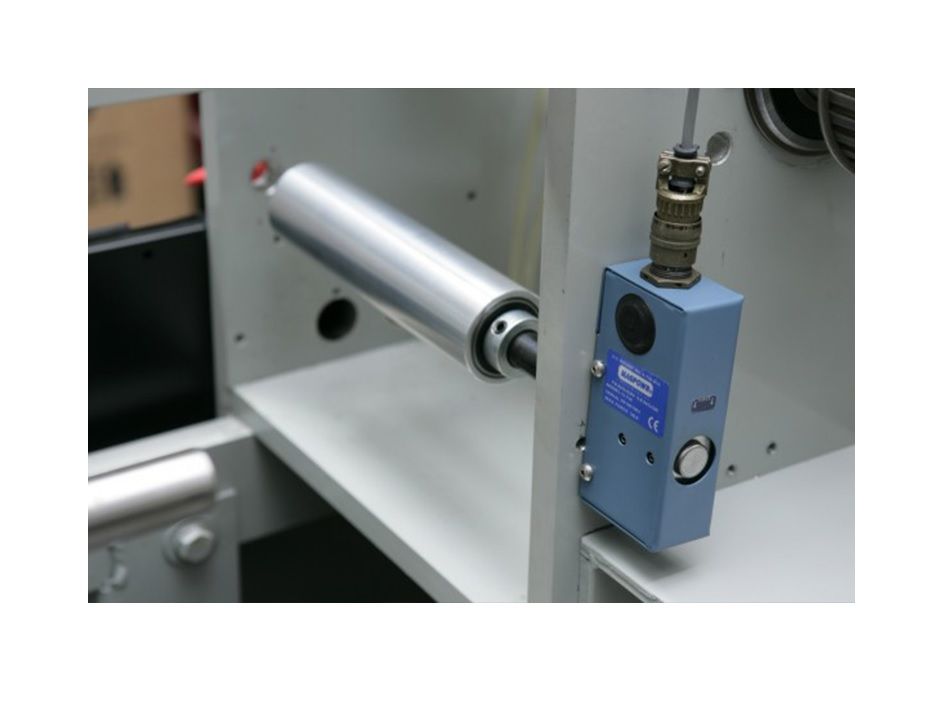

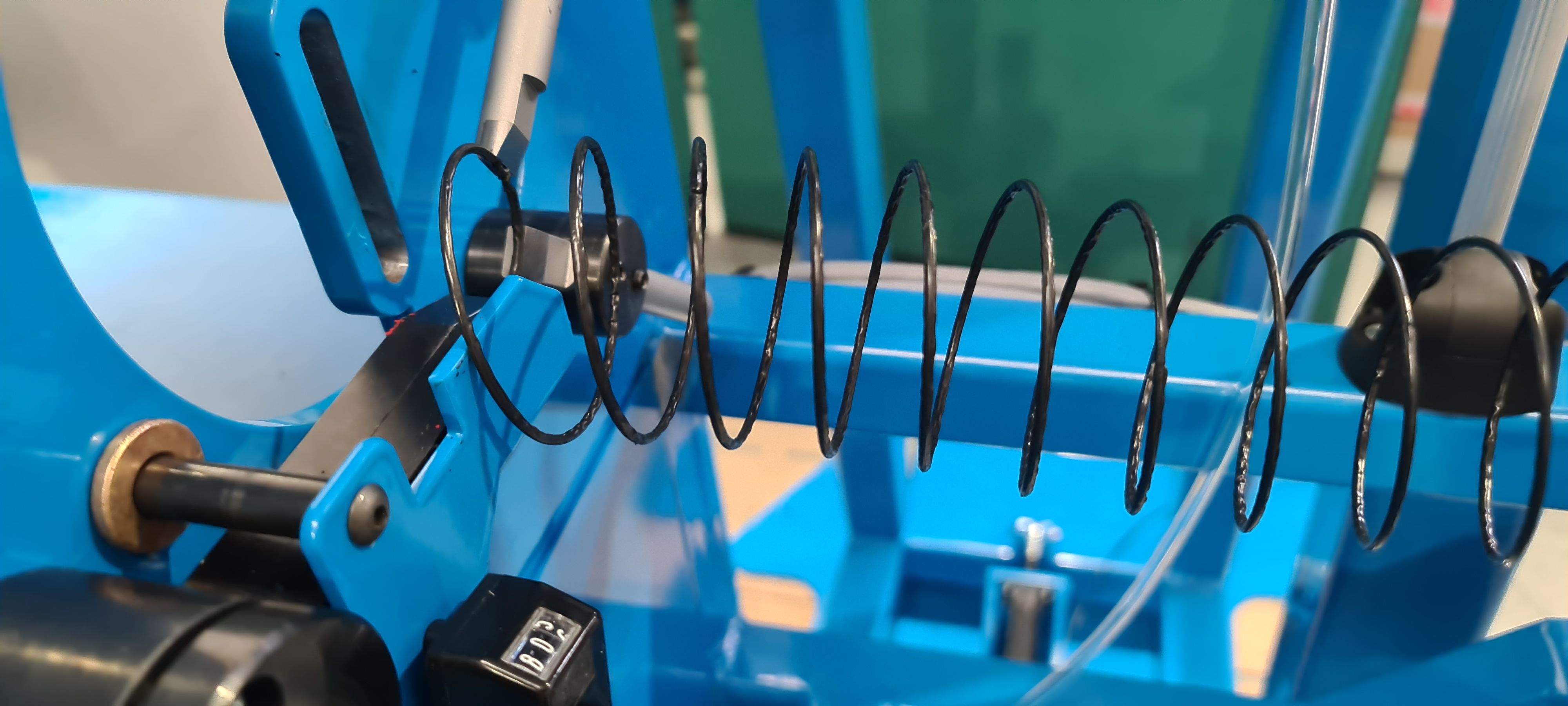

Coil Formation

Product Conveyor

What we do

Engineering Solutions

Motion Drives and Controls provide the complete Engineering solution, making our customers’ life easier. Our professional team of Engineers have many years of experience in the design of machinery for the web processing industry. Whether it be a complete new production line, unwind/rewind stand or just adaptation of existing machinery, we are here to provide the solution on time and at a competitive price.

Stock Handling & Component Supply

With us you get one source dependability and one source convenience with a simple telephone call, email or fax. We welcome requests for visits to your offices or factory for sales or technical meetings, or both – our job is to provide customer benefits. We guarantee overnight delivery of stock items or same-day if needed and on site assistance to identify and solve any problems by factory-trained specialists.

Service & Repair

At Motion Drives, we offer full technical support from component selection and system integration through to installation, commissioning and after sales support. Replacements, repairs or refurbishments are all carried out in our modern warehouse and workshop in Warwick, England.

We welcome all invitations to advise on web processing issues and offer expertise in web tension and web guidance problems, PLC programming and AC/DC motor and drive selection, and we are here to provide you with a solution to your problem.

Sectors & Industries

Get in touch with us

If you are interested in starting a partnership with us, or need any other information about products or sectors, please get in touch today to see how we can help you